The issue of efficiency and safety at the workplace has never been as crucial in the modern business environment that is fast-paced and requires efficiency. Transporting heavy commodities across the stores may be time-consuming and dangerous in the absence of the right machinery. Most firms are finding that by incorporating special lifting solutions, manual handling and operation delay are minimized.

Many companies are progressively embracing commercial cargo lifts to facilitate their companies. These lifts ensure the efficient and safe vertical transportation of the goods at a lower cost of labor and lesser injuries at the workplace. In manufacturing plants and warehouses with lots of traffic, the cargo lifts have turned out to be a common purchase for companies wishing to enhance productivity and workflow.

Understanding Commercial Cargo Lifts

An inventory system that is mechanical and forms a system used in the transportation of heavy materials to the various levels can redefine the way a business is conducted. They are also specially designed with a bigger load capacity and high frequency of use unlike passenger lifts in homes or offices, as explained in our complete commercial lift guide.

Knowing the meaning of cargo lift, businesses will be able to make their decisions in upgrading the facilities. In the case of a warehouse in Singapore that manages hundreds of deliveries each day, a cargo lift can be used, and it will greatly decrease the downtime and make the logistics process more efficient. In this regard, commercial cargo lifts are not merely efficient equipment.

What is a Cargo Lift?

These lifts are those lifts that are used to transport goods and not human beings, much like dumbwaiter lifts. They are mainly used to transport bulky or heavy objects with safety across the floor in a commercial or industrial set up.

The cargo lift meaning explains why such systems are different compared to the conventional passenger lifts. A cargo lift is different to residential elevators as it does not pay much attention to comfort but, instead, it is designed to be durable, carry a lot of weight and to be used regularly. This renders it as indispensable to warehouses, factories, and other storage spaces in retail outlets that demand numerous lift sessions per day.

Key Features of Cargo Lifts

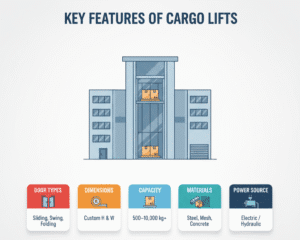

The features which need to be understood to choose the right system are some essential ones:

The features which need to be understood to choose the right system are some essential ones:

- Cargo lift door: it comes with sliding, swing or fold doors depending on the loading operations.

- Cargo Lift Dimensions: This lift ought to fit the building layout with maximum cargo space.

- Cargo Lift Size: The right size that is chosen makes sure that the standard loads are properly taken care of without over traffic of the system.

- Load Capacity: Each lift has a limit on weight lift which is crucial with regard to safety and efficiency.

- Material Construction: Good materials are used hence making it durable even with excessive use.

- Power Source: Electric and hydraulic comes in use, depending on the needs of use and load.

Knowing these main features enables the businesses to select a cargo lift that fits in its operational requirements. The correct choice will guarantee the efficient work process, the reduction of downtime, and the possibility to maintain numerous cargo raising sessions within a day, offering safety and efficiency to warehouse or industrial activities.

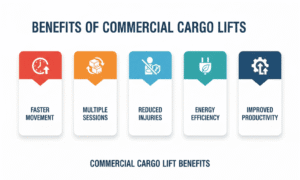

Benefits of Using Commercial Cargo Lifts

In the current business environment, there are growing demands of efficiency and safety in business operations. The transportation of heavy goods by hand is slow, laborious and may cause accidents. The new solutions in terms of modern lifting allow companies to optimize the workflows, as well as minimize the risks of operations.

In the current business environment, there are growing demands of efficiency and safety in business operations. The transportation of heavy goods by hand is slow, laborious and may cause accidents. The new solutions in terms of modern lifting allow companies to optimize the workflows, as well as minimize the risks of operations.

Cargo lifts also enable the businesses to transport materials across the floors in a swift and safe manner, supported by professional lift installation. Higher load limits of these lifts means that they can have several cargo lift operations in a day that saves time in delays and enhances productivity, when paired with certified maintenance services. The facilities equipped with electric cargo lifts also enjoy energy efficient operations that allow businesses to save on long term power expenditures whilst enjoying high speed logistics. The increased cargo lift capacity will make sure that warehouses, factories, and retail centers are able to handle the bulk shipments without jeopardizing the safety.

Improved Safety and Compliance

The safety of work at the place of work is one of the priorities of any company that handles heavy loads. Manual lifting also brings a high probability of injuries and operational risks, and this may affect the welfare of the employees and the sustained operation of the business.

The cargo lift is designed in a way that it can minimize these risks by transporting heavy goods in a safe manner. Having the well-established cargo lifting capacity, the business will avoid cases of overloading and safety rules will be adhered to through expert lift installation. The inclusion of cargo lifts in the normal practice does not only safeguard the workers, but also helps in the compliance with the occupational safety standards, thus generating the peace of mind both to the manager and the employees.

Increasing Productivity and Efficiency

The full process of a warehouse is prone to numerous rounds of transportation of items, which postpones the production and delivery time. Vertical transport automation leads to high efficiency in workflow.

Commercial cargo lifts help in making the materials move faster by having continuous cargo lifts which cut off the bottlenecks and employees are left free to attend other important activities. Higher load capacity means that these lifts can move bigger loads in less frequency thereby making business activities and productivity faster. The workflow management and turnaround times are usually recorded to have improved in companies that are using these systems

Types of Commercial Cargo Lifts

Lifting solutions needed by different businesses are different. The selection of the right lift will guarantee the efficient work and the efficiency of the work.

There are commercial cargo lifts of a hydraulic type, electric type, and pneumatic type that offer different advantages. Electric cargo lifts are economical and can be used frequently whereas hydraulic lifts have high load capacity when it comes to heavy materials. Singaporean companies tend to consider the lifts according to their size and regulations, and, therefore, it is critical to choose a model that would comply with the operational and local standards.

Knowing the peculiarities of both types, the business will be able to coordinate investment with the working processes and long-term development.

Electric Cargo Lifts

A large number of new-day warehouses are dependent on the use of automated solutions to keep their productivity at a steady level. Electric cargo lifts are made to contain frequent use, and they consume low power.

These lifts have been associated with the efficient use of power that makes them dependable in terms of consumption of less cargo lift power. They are able to achieve this because of their high resistance to wear and tear and as well as low maintenance, which makes them fit in high-paced environments to complete numerous cargo lift sessions throughout the day and maintain their performance. Electric systems provide business units with an opportunity to enjoy efficient operations, low operating expenses, and sustainable operation over the long run in cargo transportation.

Hydraulic Cargo Lifts

Other plants require the transportation of very heavy items which are beyond the normal lifting limits. Such applications should use hydraulic lifts which are designed with good construction and high load capacity.

A hydraulically designed cargo lift is capable of carrying heavy cargo lift without compromising on safety levels. They are frequently applied in the manufacturing facilities and industrial warehouses where heavy loads need to be moved regularly. With the help of hydraulic solutions, the businesses can enhance the efficiency of the workflow and minimize time wasted due to manual lifting or less powerful lifts.

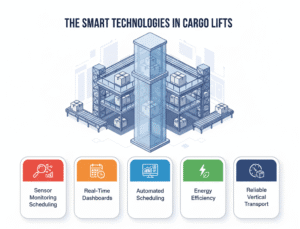

Future of Commercial Cargo Lifts in Smart Businesses

Material handling in factories and warehouses are changing due to advancement in technology. Modern facilities are now becoming automated, with monitors that are smart, and designs that consume less energy.

With these needs, cargo lifts are changing and are providing new safety features, improved load handling, and connection with commercial lift systems. Cargo lifts in business are becoming popular in Singapore and track the performance of lifts and anticipate the maintenance requirements. The high cargo lift capacity and low power consumption in the cargo lift results in the company being able to handle heavy workloads at a minimal consumption of energy expenditure. These lifts will be important to future-ready logistics operations as automation becomes common.

The Smart Technologies in Cargo Lifts

Nowadays, warehouses are becoming smart and ensuring efficiency in operations. The sensor, automated scheduling, and real-time monitoring will enable managers to monitor the usage of the lifts and ensure the continuity of the working process.

Energy efficient lifts are electrically powered to reduce the operation expenses at the expense of facilitating numerous cargo lift operations per day. Innovative controls are able to increase reliability, reduce downtimes, and enable firms to maximize vertical transportation without requiring more labor. Through technology and sound lift design, the facilities will be able to make sure that the goods move safely and efficiently at all levels.

Choosing the Right Commercial Cargo Lift Supplier

To be reliable in the long term, it is crucial to choose a supplier with a good reputation, such as trusted lift providers. Experience, after sales services, and adherence to safety regulations are some of the aspects that companies should take into consideration.

Singaporean suppliers usually offer solutions to building layout, cargo lift size and cargo lift capacity. Collaborating with a reputable vendor guarantees the presence of professional installation, quality cargo lift repair, and continuous maintenance of the cargo lifts to enable businesses to optimize their ROI and operate without disruptions.

Conclusion

Making investments in commercial cargo lifts will allow businesses to increase efficiency, safety, and reliability of workflow. Such systems lower the level of labor dependence, manage heavy loads, and assist in numerous daily lifts of cargo and are essential to the warehouses, factory, and inch retail stores. By adapting to these lifts in its operation, companies willing to modernize its logistics infrastructure are able to have a quicker material movement, reduce its operational risks, and save on cost in the long-term.

FAQs

Q1: What constitutes the difference between a cargo lift and a passenger lift?

A cargo lift is created with one purpose to transport goods and heavy materials, and the purpose of a passenger lift is to transport people. The cargo lifts are concerned with quantity, longevity, and usage.

Q2: What is the appropriate cargo lift size?

The correct size will be based upon the normal load size, the layout of the building and the frequency of use. The volume of shipment and available space are used to determine the lift to be used.

Q3: Do electric cargo lifts use less energy as compared to hydraulic lifts?

Yes. Electric cargo lifts are usually less powered and can be used in frequent usage whereas hydraulic lifts are used in cases where the load is very heavy.

Q4: Cargo lifts: How often should commercial cargo lifts be serviced?

Frequency depends on usage. Lifts with several cargo lift sessions a day are to be frequently inspected in order to provide safety and good performance.

Q5: Is it possible to customize the cargo lifts to meet the requirements of a warehouse?

Yes. Dims, load capacity, door types and operational requirements Lifts can be geared to fit workflow and space requirements based on dimensions, load capacity, door types and operational requirements.