The safe, reliable and efficient systems are needed in industrial environments that enable smooth flow of material. A small freight elevator is created precisely with this in mind- to provide coordinated vertical transport of goods, pallets, equipment and bulk materials. These lifts ensure that businesses save on manual processing, enhance workflow, and ensure similar levels of productivity on various floors.

They are small, strong and can work even in challenging workloads which are the reasons why industries like them. These elevators are an important connection between storage, production, and distribution whether it is in warehouses, manufacturing units, or logistics hubs.

What Does a Freight Elevator Meaning Represent in Industrial Settings?

A freight elevator meaning typically refers to a heavy-duty system of lifting that is used to move goods in facilities that rely on an industrial elevator guide for proper planning. It is used in industries to enable continuous load operations, high cycles and rough operations.

The Way It Compares to Passenger Lifts

Passenger lifts are more concerned with comfort and appearance where the freight elevators are concerned with strength, durability and increased capacity to carry more weight. Their inside is reinforced and the construction can fit bulky or irregularly shaped objects.

Major elements which are applied in industrial designs

The industrial elevator systems are usually designed with reinforced doors, heavy duty motors, steel cabins, heavy guide rails and impact resistant flooring to accommodate goods during movement.

The Freight Lift Meaning in Contemporary Facilities

The freight lift meaning implies a vertical system of material transportation in industries, where an industrial lift guide often defines capacity expectations. It assists in the transportation of goods fast yet safely and efficiently.

Why Freight Lifts Are Essential for Material Flow

Such lifts minimize the bottlenecks, enhance the flow of work across the different floors, and provide a smooth flow of coordination between the departments of storage and production.

How a Small Freight Elevator Works in Industrial Environments

A small freight elevator is a motor-driven elevator that uses a sophisticated setup of motors, pulleys and lift systems to lift and lower the cabin in a carefully controlled manner. It can be traction-based, hydraulic based, or mechanical chain-based, depending on the design, which provides it with the reliable and stable lifting even with heavy loads. Various safety functions are also fitted to industrial models like emergency brakes, overload sensors, cabin locking systems and interlocked doors, which combine to secure the cargo and operators in industrial goods lifts. These characteristics render the small freight lifts effective, enduring, and secure options of transporting products within the industrial context.

Types of Small Freight Elevators Used in Industries

There exist multiple varieties of small lifts that are used in the industry depending on the load and construction of the building.

Hydraulic Freight Elevator Systems

A hydraulic freight elevator is designed with the hydraulic piston for steady lifting, similar to systems detailed in a hydraulic lift industrial guide used in factories. which props the lift of the cabin in a steady and smooth manner, so it would best fit low-rise buildings or occurrences that require a strong lifting force. They are also affordable, maintainable and can carry very heavy loads hence their popularity with many small scale industrial tasks.

Traction-Based Models

Traction lifts use steel rope, counterweight and motorized hoists that provide a vertical movement that is accurate, energy efficient and smooth. They are applicable to medium-rise, and industrial buildings where people have to make journeys at high rates frequently. Traction models are robust in performance, and have a high level of durability and reliability even when used daily.

Selecting the Right Freight Elevator Dimensions

The freight elevator dimensions determine the capacity of the lift to the size of goods it can hold.

Space Requirements/ Shaft Planning

Proper shaft width, height and pit parameters will make it possible to perform a lift installation safely without significant alterations in the building. Efficient use of the space, easy installation, and easy future maintenance are made possible through proper planning. Designing the layout at the initial stages prevents the unnecessary expenses associated with making changes and allows the elevator to blend into the building.

Pit Depth Requirement and Overhead Requirement

The overhead space should always be used to place machinery, pulleys and safety buffers. Effective clearance helps to avoid stress at the system and achieve its smooth movement. Proper pit depth and overhead space enhance the safety of operations and provide them with the possibility to upgrade without significant structural modifications. Vibrations are also reduced by careful measurements, which increases the life of the elevator.

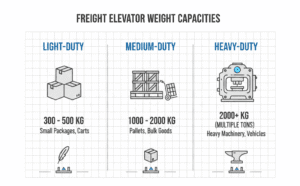

Freight Elevator Weight Capacity

Understanding the freight elevator weight capacity is essential for selecting the appropriate system to be used in industries. The capacity of weight is different based on the type of load, the design of buildings and the purpose of use. Industrial elevators are typical with a range of 300 kg in case of light-use systems and a number of tons in cases of heavy-duty transport.

The machinery, palletized goods and bulky items are also achieved through heavy-duty units whereas cartons, boxes and smaller and lighter loads can be served better by light-duty elevators. Selection of the right capacity also promotes safety in operation, eliminates overloading, and the efficiency of material handling in any industrial facility.

Breakdown of cost of freight elevators used by industrial buyers

Determining the freight elevator cost assists the businesses to plan their investment effectively, and allocate finances to the short term installation cost, and also the long term operating cost.

Installation Cost Factors

Prices vary based on the load capacity, the system type, the civil works of the shaft, the control systems and the travel height. Hydraulic models tend to be cheaper to obtain. Other considerations like dimension of custom cabin, optional features and compliance with the local safety requirement may also affect the overall cost of installations.

Long-term maintenance and ownership Costs

The costs of maintenance, inspections, replacement, and energy are added up to the lifetime costs. The cost of quality components in the long-term is minimized. Proper maintenance is known to not only increase the life of the elevator but also eliminates unforeseen outages that may interfere with the industrial process.

Top Freight Elevator Manufacturers for Industrial Use

The selection of reputable freight elevator manufacturers will also provide safety, longevity, and long term value in the industrial operations. Quality components, good service and technical support are also availed to needed components through trusted manufacturers.

Evaluation Criteria for Choosing a Manufacturer

Find certifications, load testing, after sales support and customization. Their experience of similar industrial projects and their ability to address certain requirements of these operations are also to be considered.

Comparing Local vs International Brands

Domestic brands might be faster and cost less to ship, have lower prices and offer quicker service whereas international brands are technologically advanced, higher quality standards as well as long-term dependability. Comparing the two will make you settle on a manufacturer whose needs and costs are probable to suit your facility.

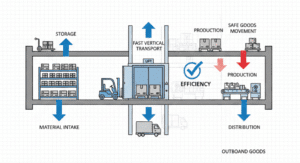

Industrial Applications of Small Freight Elevators

A small freight elevator is important to many industries because it ensures the maximization of vertical flow of materials and efficiency in operations. It facilitates the flow of pallets within warehouses and distribution facilities, replenishment of stocks and order picking on various levels.

The same manufacturing plants and workshops may use such elevators to move raw materials, semi-finished goods and even the tools according to the production areas easily, without a lot of manual labor and facilitating the workflow in the entire plant.

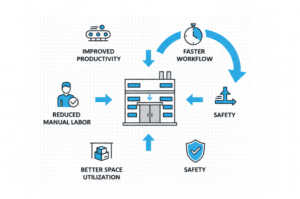

Key Benefits of Using a Small Freight Elevator in Industrial Operations

- Improves performance of departments.

- Better Productivity and Velocity: Goods are hurried around among the floors, and decreasing downtime and augmenting the production periods.

- Less Manual Work and Less Risk of Injury: This reduces manual labor, avoiding work-related traumas as well as limiting the number of tasks that require manpower.

- Improved Space Use: Liberates space on the floor through lessening the use of ramps or manual transport corridors and restructures facility design.

Requirements of installations of an Industrial Freight Elevator

The correct lift installation is important in terms of performance, safety, and reliability. Structural requirements like the space available on the shaft, the strength of the wall, and the strength of the entire building should be evaluated before it is installed to ensure that the system fits perfectly with the building. Moreover, the elevator should be designed in accordance with the industrial safety standards, electrical features and hydraulic system controls, which ensures safety in the uses and complies with the requirements of the regulatory standards alongside facilitating efficient and competent vertical material transportation.

Maintenance Essentials for Long-Term Efficiency

Inspections should be made a routine to ensure that the elevator systems are in proper operation. The routine inspections of the parts like ropes, pumps, motors, cabin floors, and control systems also ensure that the downtime is not a surprise and performance is smooth. Also, strange sounds, stuttering, or malfunctioning doors are indicators of the necessity of professional maintenance.

Early elevator maintenance and repair also helps to prolong the life span of the elevator and reduces operational interruptions as well as ensuring that the working environment is safe to all users.

The How-To Guide to Selecting the Best Small Freight Elevator to fit your industry needs

The choice made should be in accordance with the workflow and the design of your building, so that the elevator should fit perfectly well into the day to day activities, and as well as help maximize efficiency.

Factors to Consider Before Final Decision

Whilst choosing your system, check the weight capacity, dimensions, speed, reputation of the manufacturer, and its maintenance needs and also consider the optional features that will boost long-term productivity.

When to Upgrade Your Existing System

Upgrade is required where your existing system is having issues with load capacity, frequent breakdowns, or it is no longer safe, and partnering with a trusted elevator service provider ensures seamless operations. Proactive upgrades will facilitate avoiding expensive downtimes, lessen the burden of maintenance costs, and enhance operational safety in general.

Conclusion

The modern industrial functioning heavily depends on the efficiency of vertical transportation as the means of ensuring the safety and reliability of material, equipment, and products movements. Whether it is knowledge of weight capacity and size, cost analysis, manufacture and installations, proper planning will guarantee the most performance and value in the long run. With an appropriate choice of a system, maintenance routines, and the necessity to upgrade the equipment, businesses will be able to increase productivity, decrease the number of manual laborers, and simplify the working process. Having a good quality small freight elevator in the end justifies operational efficiency, safety and sustainable expansion in the warehouses, manufacturing units and distribution centers.

Frequently Asked Questions

What is the purpose of a freight elevator in industrial conditions?

A freight elevator is the type of elevator that is installed in warehouses, factories, and logistics centers to move goods, pallets and equipment up and down. It enhances workflow, lessens manual labour and makes heavy or bulky materials safe and efficient in their movements.

What is the difference between freight elevators and passenger lifts?

Small freight lifts, unlike passenger lifts, place more emphasis on durability, goods load carrying capacity and safety. They are reinforced, heavy duty makers, steel door, and impact resistant floor, which makes them perfect in the transportation of machinery, pallets and industrial supplies.

What influences the cost of the freight elevators?

The price of freight lifts varies according to the load, the type of the system (hydraulic or traction), the structure of the shafts, the height of the travel and additional options. Maintenance, inspections and power consumption in the long run also affect total investment. Effective budgeting relates to proper planning of the businesses.

What is the appropriate size of a freight elevator?

Choose dimensions depending on the size and weight of merchandise, shaft clearance, depth of the pit and overhead clearance. Proper planning makes operation of the system efficient, avoids any changes, and manages to upgrade the system in future without affecting its efficiency and safety.

How often and when do I upgrade my current freight elevator?

The reason to upgrade is that the system is either having difficulties regarding the load capacity, is prone to breakdowns, or has lost its safety standards. Efficiency, minimization of downtimes, and safe handling of material within the industrial operations are enhanced by prompt replacement.