The modern manufacturing facilities and warehouses use industrial goods lift to control the way of vertical transport. The lifts allow transportation of materials, equipment, and finished products to another floor without the use of much manual labor, and without much risk of having accidents at work. As the need in the elevator industry rises, the companies are finding ways of improving the efficiency of operations as well as increasing safety and minimizing the downtime.

A quality warehouse goods lift will provide a smooth working process, enhance the vertical space use, and be reliable in the long run, which makes it one of the most important investments of the current industry.

What Is an Industrial Goods Lift?

An industrial goods lift is a robust platform that is used to carry merchandise, equipment and materials up and down the levels of warehouses, assembly plants and warehouses. These lifts are designed to carry heavy loads, are used regularly and are designed to withstand industrial conditions unlike residential or commercial elevators. For more details, see this industrial elevator guide.

The main aim of a goods hoist lift is to minimize manual operation, avoid workplace hazard and streamline the work on the various levels. The lifts allow facilities to be efficient in their operations, safely transport heavy or large objects, and sustain large-scale production or storage needs.

Key Functions of Goods Lifts in Business Operations

- Goods lifts make vertical transport easier and quicker and ensure more efficient movement of products through various floors.

- They also minimize the time wastages in warehouses and manufacturing plants by eradicating the bottlenecks, which are brought about by manual handling.

- Efficient lifts make good use of the existing storage space and ensure that inventory is well organized.

- They ensure that goods flow well in the facility to facilitate continuous operations.

- The inclusion of industrial lifts improves the overall productivity, protects the workers, and provides a high level of reliability in the transport of the materials.

Types of Goods Lifts and Their Uses

Goods lifts are of various types which are aimed at satisfying various operational requirements. Hydraulic goods lifts can be used when the building does not exceed a limited height and has a smooth movement with low cost of installation. Taller structures should have traction-based systems which offer efficiency in terms of producing energy and high speed of travelling. Goods lifts come in different pallets and equipment sizes which are useful in warehouses that have a wide range of goods. The type of lift used in the case is determined depending on the load capacity, the floor height, the frequency of use, and available goods lift dimensions so that the materials are transported in a safe and efficient way.

Industrial Freight Lifts

Freight lifts have the design to carry huge machinery, raw materials and heavy goods in harsh conditions. They are strong in nature, durable, and can carry high capacity loads hence they are applicable in manufacturing plants and in large warehouses. An appropriate goods lift size is chosen so that goods can be delivered without operational delays or breakages and can be very reliable to operate over a long time in industries.

Warehouse Goods Lifts

The Warehouse lifts are medium to light lifts which enable free movement of stock between the floors. The systems enhance efficiency within the distribution centers, retail storage units, and multi-level warehouses. A warehouse goods lift that has been appropriately set up will allow inventory to be transferred efficiently and with minimal risk, optimal storage arrangement and simplified day-to-day procedures.

Industrial Goods Elevators Components and Working Mechanisms

The industrial lifts are either hydraulic or traction based and have a motor, pulleys and cables that propel the up and down motion. The lift control panel handles the stopping, safety and speed functions to make sure that there is a smooth and reliable operation. Monitoring systems assist in identifying overloads and maintenance requirements and avoiding accidents and downtimes. Proper installation of lift for goods systems is essential to maintain performance, safety, and adherence to industrial rules, as detailed in our industrial lift guide.

Safety Standards and Compliance for Industrial Goods Lifts in Singapore

The lift operations in industries are vital as far as safety is concerned. Adherence to international and local standards, e.g. EN 81, will help to ensure the observance of the goods, lift safety instructions and reduce the risks to the personnel and equipment. During operation, emergency brakes, overload sensors and automated control systems ensure the safety of materials and workers.

Periodic servicing, following instructions of the manufactures and professional maintenance services provided by reliable goods lift manufacturers contribute even more to reliability and job safety.

Industrial Goods Lift Price Guide

A goods lift may cost differently based on its capacity, type and features. The hydraulic systems tend to be cheaper in low rise buildings whereas traction lifts and custom platform lifts may cost more because of the higher speed and size. The overall price may also be affected by installation, safety systems and maintenance packages. Quotations of various goods lift manufacturers are compared and thus businesses are able to make wise decisions depending on their budget and operation needs, after consulting a reliable elevator service company. High-quality systems are guaranteed to last long and pay back.

Selecting the Appropriate manufacture of Goods Lifts

It is important to choose a good goods lift manufacturer to ensure performance can be reliable, safe and have a long service life, which starts with Expert lift installation services. When assessing the suppliers, consider the certifications, experience and past portfolios of the project. The availability of spare parts, after-sales support, and technical expertise is also of importance to make sure that the system remains efficient. Cooperating with a well-known manufacturer is the insuring factor in the professional installation, maintenance and compliance with safety standards so your investment in an industrial goods lift is not in vain.

Maintenance and Best practices

Maintenance should be done on a regular schedule so that lift performance and safety are maintained. The use of hydraulics, pulleys, sensors, and control panels are some of the components that should be checked on a regular basis. Effective lubrication, cleaning and preventative servicing can be used to minimize downtimes, longevity of equipment and enable a smooth running of the warehouse, supported by reliable lift maintenance services. Adherence to goods lift safety instructions guarantees the safe and uninterrupted utilization of the same as well as reduced operation inconveniences.

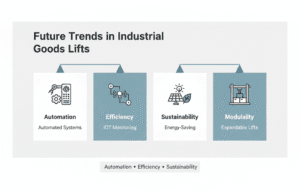

Trends in the Goods Lifts of Industry in the Future

Automation, intelligent monitoring, and energy-saving systems are becoming accepted in the industrial lift industry. IoT controllable systems permit real-time monitoring of performance, predictive maintenance, and lower the operational expenses. Expandable and modular lifts are designed to serve large warehouses with increasing size, and also some environmentally friendly designs reduce energy usage.

Companies that invest in the latest platform lift goods systems enjoy increased efficiency, sustainability and better workflow management.

Conclusion

The installation of an industrial goods lift is a good move that improves on the safety, working efficiency, as well as vertical movement of materials. The correct selection is conducted according to type, dimensions, price, and reliability of the manufacturer, which guarantees benefits in the long term. These lifts eliminate manual labor, maximize warehouse space and enhance the speed of the workflow, which makes them invaluable in the contemporary industrial facility. The knowledge of the requirements of the installation, safety standards, and future trends helps businesses to make informed decisions in order to maximize productivity, safety, and operational success of their lift investment.

Frequently Asked Questions

What is the purpose of an industrial goods lift?

Industrial goods lifts help to move heavy products, materials and equipment among floors of warehouses and factories. They are minimizing manual work and providing safe and efficient transport of goods vertically.

How much does a goods lift cost?

It has a number of options depending on the type of lift, its load capacity, and features. A hydraulic lift is cheaper and traction lift and custom platform lift are more expensive because of the faster speed and greater size.

What is the best way to select the correct manufacturer of a goods lift?

Choose the manufacturers who are certified, experienced and have good post sale support. The main ones are reliability, availability of spare parts and compliance with safety standards.

What are the safety characteristics that an industry elevator should possess?

There should be industrial lifts that have emergency brakes, overload sensors and automatic controls. Safety: A proper checklist and adherence to rules and precautions make work safe.

Which kinds of goods lifts are offered?

Typical ones are hydraulic lifts used on low-rise buildings, traction lifts used on tall buildings and platform lifts used in warehouses of the versatile type. Every one is selected according to load, dimensions and usage frequency.