Industrial plants have a tendency to need effective methods of transporting heavy pieces of equipment up and down the flights. Companies that handle warehouses or manufacturing facilities or logistics facilities require systems with safety, reliability, and high load capacity. In this all inclusive guide, we are going to look into requirements of installation, cost, and safety of hydraulic lift. In types of lifts to standard of operation, this guide will help the industrial managers make the right choice and have an idea of the technical and practical side of lifting installation.

What a Hydraulic Lift Is and the Workings of Hydraulic Elevators in the Industry

A hydraulic elevator lift utilizes fluid pressure to lift the platform or cabin with respect to the ground. It is able to take heavy loads in a smooth manner by transforming hydraulic energy to mechanical motion. The technology is used in industrial applications due to its ease and modification to various floor heights. The efficiency of the system relies on the pump, cylinder and valve assembly enabling it to lift cargo securely with minimum maintenance. Understanding how hydraulic elevators work is essential for operators and facility planners, ensuring that the load is handled correctly, it is energy efficient and safe to operate in industrial settings, as detailed in our industrial elevator guide.

Types of Hydraulic Elevator Lifts used in industries

There are various choices that businesses have in case they choose hydraulic to use in industrial purposes, which can be better understood in the industrial goods lift guide. The hydraulic freight elevator is created to handle heavy items and the hydraulic vertical lift fits the narrow areas and tall buildings warehouses. Passengers movement facilities may also take into consideration hydraulic passenger elevators which are more focused on safety and easy operation.

All types possess different load capacity, speed and structural requirements. The correct lift will be determined by the operational requirements, the space and frequency of use. Choosing the right set up is a way of making the system as efficient as possible, and lowering the wear and tear on it.

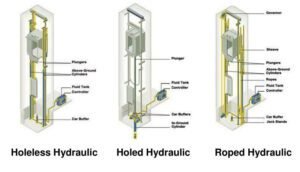

Roped Hydraulic Elevator vs Holeless Hydraulic Elevator

Roped hydraulic elevators and holeless hydraulic elevators are usually assessed in industrial locations. Roped lifts are those ones that rely on the cables together with hydraulic cylinders which enable more length to be covered by the lifts in the taller buildings. Holeless hydraulic lifts are also small and do not need a deep pit to be installed, which means that they can be used in areas with structural limitations.

This knowledge of the differences will assist the facility managers to align the lift design with the conditions of the building, load requirements, and maintenance expectations.

Hydraulic Elevator Components Elucidated

There are a few common components of a typical hydraulic used by industries, such as a cylinder, a pump, valves, an oil reservoir, and a control system. These hydraulic elevator components work in tandem to manage load movement and ensure smooth operation. The lift platform itself of the hydraulic elevator lift is made tough enough to support industrial loads.

An adequate knowledge of these elements enables operators and maintenance technicians to track the performance level, determine the possible problems, and plan preventive maintenance to minimize downtime and achieve operational efficiency.

Industrial Hydraulic Installation Requirements

A lift is to be installed and properly planned to meet structural and operational requirements. Facilities should ensure that the shaft or the area is ready, it should have enough electrical supply and also structurally support heavy loads, which is why proper lift installation is critical. It is very important to select the correct design like a hydraulic passenger elevator depending on the priority given to human movement or the freight transportation.

Proper installation also means evaluation of the ventilation needs of the pump room, installation of safety switches and confirmation of the site that meets the local building code and safety standards. Properly designed installation will make the lift a reliable machine, which will fulfill the needs of industrial facility workflow.

Site Preparations and Conformity Inspections

Prior to installation it is necessary to analyze the site preparation. Hydraulic lift Singapore standards in areas such as Singapore involve structural check, electrical and safety certifications. Checks include pit depth, shaft size as well as the correct positioning of mechanical components. By making sure that the site is in accordance with all regulatory standards, the time delays are kept to a minimum, unnecessary costly changes are avoided and the lift is theoretically safe and effective through proper lift installation services.

Traction vs Hydraulic Elevator: The Major Differences In Industrial Application

Traction vs hydraulic elevator systems are some of the decisions commonly compared by the industrial decision-makers, and understanding these choices can be found in the industrial lift guide. Traction elevators operate with counterweights and rope and usually have higher speeds whereas hydraulic elevators operate on the pressure of fluids to provide vertical movement.

Understanding the difference between traction and hydraulic elevators is essential when evaluating cost, energy use, load capacity, and maintenance needs. Hydraulic systems are suitable in moderate-rise industrial buildings because it is simple, more reliable and less expensive to install. Traction lifts, on the other hand, can be used in taller buildings when high-speed is required. An assessment of these factors guarantees the appropriate decision of operational efficiency.

Advantages of Hydraulic Lift for Industrial Operations

Hydraulic elevators have been used in industries due to its strength, durability and capability of working with heavy materials. The advantages of hydraulic lift include the ease of operation, less use of energy at moderate height as well as small space requirements in comparison to traction elevators. The lifts also offer high accuracy of the stopping point, easy fitting into the existing structures and high levels of safety thus making them fit perfectly in warehouses, factories and logistic centers. Companies are able to choose lifts deploying these advantages to maximize the working process and reduce operational risk.

Hydraulic Safety Standards and Protocols Lift

The lifts used in industries should be safety-regulated to avoid accidents and to be able to work without difficulties. There are the standard practices such as load testing, over-speed protection, emergency braking system, and appropriate training of the operators. Regular checkups are done to check the integrity of the cylinders, the levels of the hydraulic fluid and valves.

The certified hydraulic elevator system is applicable to ensure that the safety equipment is operating as required without a high chance of exposing the staff and cargo to dangers. The compliance with the safety also facilitates insurance cover and the local legal standards, which is particularly applicable in industrial facilities where a lot of heavy-duty lifts are used.

Maintenance Procedures to reduce downtime

These lifts have a long life and efficiency that is guaranteed by regular preventive maintenance. Lift Maintenance and repair is essential to keep cylinders, valves, and other components functioning safely and smoothly. The planned maintenance will minimize the unforeseen downtime and service life.

Through systematic maintenance procedures, industrial plants are able to have continuity of operation, optimal productivity, and reduce costs of repairs in the long term.

Breakdown of Industrial Hydraulic Lifts Cost

There are various cost considerations in hydraulic elevator lift in the industry. The initial hydraulic elevator cost includes the platform, cylinder, pump, control systems and installation labor. There can be extra costs that are brought about by structural changes, construction of pits and adherence to local policies.

Depending on the desired functionality, optional features can be provided (e.g. automation or hydraulic cabinet door lifts), at a higher cost. Through the summation of investment, businesses will be capable of planning budgets efficiently and determining the return on investment considering the maintenance, use of energy and the possible acquisition of productivity.

Hydraulic Cabinet Door Lift: Industrial Additions

A hydraulic cabinet door lift can be installed in some industrial premises to move small goods or special cargo. They are small systems that are better placed at work and they help to improve safety during the transfer of delicate items between the floors. They are used to supplement bigger freight or passenger lifts, make it efficient and space-saving at the factories or logistic centres.

Hydraulic Lift Singapore: Selecting an appropriate Supplier

An important factor in the performance of industrial lift is the choice of an honest vendor. A reliable elevator service company will make sure that the standards of the country are followed, they will have experienced people to do the installation and they will offer maintenance services.

The assessment of the credibility of the suppliers, the history of the work, and the time spent on responding to the orders assists the business establish long-term operational stability. Lift providers would also provide access to spares and professional technical assistance.

Final Checklist for Buying an Industrial Hydraulic Lift

- Establish the necessary load capacity, height, duty cycle and dimensions of the platform.

- Determine safety measures, emergency procedures and maintenance needs.

- Compare suppliers, warranties and services.

- Optional items to be considered include the hydraulic vertical lift or small goods handling feature.

- Make sure that the lift that was chosen fits the operational needs, optimizes the workflow, and meets the safety standards.

- When planned well, this will minimize downtimes and maximize ROI.

Conclusion

Selection of hydraulic elevators depends on the nature of the industry where the lift is to be installed and the factors that matter most to those companies in regard to safety, efficiency and good material handling. Knowing what to install, operating expenses and what safety measures to establish will enable businesses to make good choices. Possibly a freight system, a passenger one or a vertical system, a properly designed hydraulic lift guarantees a smooth flow of operations, reduced downtime, and long-term value.

Frequent service and proper choice of vendors also contribute to increased performance, which makes it an intelligent investment in any industrial business.

Frequently Asked Questions

What are the principal parts of a hydraulic elevator?

A standard hydraulic lift in an industry has a cylinder, a pump, valves, oil tank, and a control system. These elements collaborate to bring safety and easiness to the vertical movement of massive items.

How does a hydraulic elevator operate?

Hydraulic elevators involve the use of fluid pressure to raise the lift up and down. The system has accuracy and reliability of movement that is appropriate in industrial loads.

What is the distinction between traction and hydraulic elevators?

Traction lifts rely on more speed through the use of ropes and counter weights whereas Hydraulic are based on the use of fluid pressure. They are less complicated, more dependable and suitable in the case of moderate rise industrial buildings.

What are the advantages of lifts within an industry?

They are durable, can carry heavy loads, they are energy-consuming at medium heights and they do not occupy much space. They are also accurate in stopping and simple to integrate with the existing structures.

What are the safety standards of these lifts?

Lifts that are used in industries must have load testing, emergency brake, over speed protection and they need to be well trained on how to use them. This is done through compliance to ensure the safety of the staff and cargo as well as to comply with the legal requirements.

What is the cost of an industrial hydraulic elevator?

The price comprises of the platform, cylinder, pump, control system and the installation work. Additional features or structural changes may add up to the costs according to the operational requirements.