The contemporary constructions (residential, commercial, or industrial) rely extensively on the solutions of vertical movement. Knowing the various forms of lift will assist the homeowners, facility managers and industrial operators to choose the appropriate lift system depending on space, capacity, design and usage requirements. There are no longer just lifts that are single-level passenger elevators. They lie between a small home lifting device to large and heavy industrial freight lifts, which have various configurations, power systems and safety features.

This exhaustive manual will cover all of the key lift types which will put you on extensive subpages where you can read further. You need to know all there is to know whether you are planning installation or you just want to know.

Why modern buildings need different lift systems

The way different buildings are constructed today also depends on diverse lift systems as each construction has its own operation and architectural and accessibility requirements. The needs of residential houses are to have small, silent, low-maintenance lifts to aid the daily mobility whereas commercial buildings can offer faster and high-capacity lifts to ensure continuous usage. Working conditions in industries require strong lifts that are durable, have a strong platform, and strong parts to be able to transport work equipment, pallets, and goods that are very large.

With the taller, smarter and more specialized buildings, lift requirements are now increasing to encompass energy efficiency, space efficiency, and latest safety technologies. The choice of lift systems also depends on different user groups, namely residents, customers, staff and operators. This is why it is crucial to select the appropriate lift that would guarantee performance, safety, convenience, and long-term stability in both architectural and industrial environments of the modern day.

Overview of how lifts are categorized

Lifts may be divided according to various factors, and this also enables the planners and purchasers to find the appropriate system to use in their building. The most popular classification is the division of lifts into residential, commercial, or industrial. The other approach classifies lifts using mechanical means, e.g. hydraulic, traction, pneumatic, or machine-room-less, all of which may provide different speed, load, and installation properties.

These types of lifts can also be classified based on purpose such as passenger lifts, good lifts, freight elevators, accessibility lifts, and architectural specialty. Other manufacturers base lifts on structural needs, including shaft lifts, pitless or modular lifts. The knowledge of these types will reduce the list of the possible options to the ones which fit the available space, traffic, budget, and performance expectations. Such a systematic thinking is done to make sure that all types of buildings can be fitted with the appropriate lift technology.

Benefits of understanding lift variations

Knowledge of the differences in lift is also beneficial to homeowners, architects, contractors and facility managers to be able to make informed choices in the selection of the lift system. The varieties of lifts differ in their attributes of load capacity, height of travel, speed, safety, and installation. With the knowledge of the differences, the planner can select solutions that suit the needs of users in accordance with the regulatory provisions and building requirements. It is also useful in preventing expensive errors, including picking a residential grade lift that could be used in a commercial application or an oversized industrial system that could be used on a small property.

An investigation of various categories of lifts also brings out energy saving methods, compact lifts, and flexibility in designs to be user friendly. This knowledge enhances the performance of the lift in the long-term, minimizing maintenance expenses, and ensuring that the lift is as convenient, safe, and reliable as possible during its lifecycle.

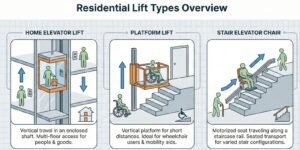

Residential Lift Types

Convenience, modern home design, aging-in-place needs, and lifts in the residence are becoming more popular. This segment includes small, noisy and power-saving lifts meant to be used in homes, villas, apartments and duplexes.

Home Elevator Lift

A home elevator lift is a small passenger lift, which is mounted indoors of the personal houses. It is usually made to accommodate 2-4 individuals and is silent and consumes little power. These lifts increase comfort, assist the elderly users and add value to the home property. These are available in different designs, which are hydraulic, traction, pneumatic, and machine-room-less (MRL) designs.

Maintenance and Safety of Home Lifts

A home elevator will be used without complications and will last long when it is maintained regularly. Monitor hydraulic fluids in the check, monitor cables and conduct periodic tests on the emergency brakes. The safety features such as intercom, sensor and alarm must be checked to ensure effective functioning. Maintaining the buildings correctly minimizes the cost of repair costs and boosts user safety, especially with regular maintenance and repair.

Platform Lift

A platform lift is an accessibility device that is used by wheelchair users and individuals with disabilities. It does not have a full cabin but has an open platform that has safety gates. It is commonly used in homes, schools, clinics and small offices. Platform lifts will occupy minimum space and can be easily installed without any significant construction, as detailed in this Platform Lift Guide. They are able to cover short distances- they are perfect on porches, split-level houses and mezzanine floors.

Platform Lift Accessibility Features

Platform lifts are aimed at enhancing accessibility with ease and safety. Widely used features are smooth start-stop controls, anti-slip platforms, safety gates and emergency stop buttons. Small size enables easy bulky fitting into small spaces. These lifts are a sure way to have a reliable mobility solution among wheelchair users and any other limited mobility person.

Stair Elevator Chair

A stair elevator chair is a mobility device that is fitted on existing staircases by elderly or disabled individuals. It has a rolling seat installed on straight or curved staircases. These lifts are cheaper substitutes of full lifts and hardly need any structural adjustment. They suit best those multi-story houses where individuals require mobility assistance but without any change in the building structure.

Installation and Usability of Stair Elevator

Stair elevator chairs can be easily installed on the straight staircase or the curved staircase. Most of the models have foldable seating, swivel, and battery backups. The controls are user friendly and seating is ergonomic, making the device very friendly and comfortable. These lifts can be easily installed and require a minimum amount of structural work making it an effective home solution of accessibility.

Home Lift Installation Cost

Knowledge of the cost of installing lift in home is a prerequisite to project planning. The prices vary according to the type of lift, the height of the travel, the construction of the pits and shafts, safety, and the cabin designs. A hydraulic lift is usually expensive; a platform lift is less expensive; and vacuum lifts are comparatively cheaper. Long-term maintenance costs, energy usage and warranty are also the factors that should be considered by the homeowner when estimating the overall investment.

Cost Considerations

Home lifts are available at different prices depending on the type, size, features and complexity of installation. Platform lifts or vacuum lifts are often less expensive than hydraulic lifts because of the equipment and installation cost. Other modifications are structural, safety systems, and maintenance, which are long term. Budget planning will make sure that the lift is efficient regarding both functional and financial requirements.

Commercial Lift Types

Commercial buildings need to be more demanding in their performance, durability and safety regulations. Commercial lifts are also designed to withstand the daily demands of large volumes of use coupled with providing speed, beauty, and dependability.

Commercial Elevator Lifts

Malls, hotels, offices, hospitals, mixed-use buildings have commercial elevator lifts. These elevators are usually of heavy passenger capacity, travel speed and sophisticated safety features. Depending on the height of the building, they can employ the traction or machine-room-less systems. Ornamental personalization like stainless steel cabins, electronic panels is typical, as explained in our Commercial Lifts guide.

Performance and Safety of Commercial Lifts

Commercial elevators are designed to be used at a high frequency and carry large passenger loads. These are the high braking systems, overloading sensors and emergency communication capabilities. The acceleration and deceleration are smooth, which makes the ride comfortable, and the safety is also made robust, to safeguard the passengers. These elevators are ideal in both the public and commercial spaces because they are properly designed and maintained and are therefore reliable and within the building safety regulation laws.

Dumbwaiter Lifts

A dumbwaiter lift is a small goods lift that is employed in restaurants, hospitals, hotels, libraries and villas in transporting food, files, dishes, and laundry and supplies. It cuts down on the manual work and increases efficiency of operations. Dumbwaiters are fitted in stainless steel cabins and run on the simple push-button controls. They are able to be used in narrow spaces with little construction.

Dumbwaiter Lifts Operational Efficiency

Dumb waiters make the workflow simpler and efficient in that they carry items between floors within a short time, which saves on time and labor expenses. They are simple to use and maintain and space requirements are low. Safe and efficient operation is achieved by proper load management and frequent inspection. Such lifts are ideal in companies which involve the frequent transfer of light products without distorting the daily activities.

Commercial Cargo Lifts

Commercial cargo lifts are powerful lifts that are used for heavy transport, as covered in the cargo lifts guide. Cargo lifts do not need the capacity to support a lot of passengers at once; their focus is on power and resistance, as well as a huge platform. They have strengthened steel frames, large load bearing capacity and levels of access.

Cargo Lifts Load Capacity and Life Cycle

Cargo lifts are designed to support heavy and uncompromising weight. Strong motors, reinforced platforms, and strong cabins guarantee reliability in the long term. Automatic gates, overload sensors and emergency brakes are some safety features that are used to safeguard both goods and operators. These lifts streamline the material management and work process of business and industry settings.

Circular Glass Lift

Glass lift is an upscale type of vertical mobility that is commonly used in architectural design consideration. Its 360 degree panoramic glass enclosure has improved visuals of the hotels, luxury homes, offices, and commercial buildings. These lifts are fixed either internally or externally and have features of being silent, traveling smoothly and in a modern design.

Design and Aesthetics of Glass lifts

Circular glass lifts are very functional and beautiful at the same time. Open compartments give panoramic windows, and the smooth movement and silent travel will make the passengers comfortable. They are commonly selected in the areas with prevalent luxury and high traffic where appearance counts. They are well maintained, which means that they will always operate perfectly and retain their stylish look in the long run.

Industrial Lift Types

Lifts used in industrial settings must have the ability to operate continuously, under heavy loads, harsh environments and have stringent safety rules. Industrial lifts are made using a sturdy material, powerful motors and stiff guide rails.

Industrial Elevator Lift

There is an industrial elevator lift, which is applied in manufacturing plants, power stations, construction buildings, and production facilities. These lifts carry heavy weights and are designed to be used in day-to-day heavy traffic. They are practical and imperative of industries, you can explore this detailed Industrial Elevator Lift guide. The majority of the models have traction or hydraulic mechanisms according to the workload.

Heavy-Duty Performance

Industrial lifts are designed to be used in the normal course of business and under heavy loads. The powerful motors, solid frames and hardwearing cabins provide reliability even during heavy loading. Safety is also provided by safety features like emergency brakes, overload sensors and fire rated parts that secure the operators and cargo. The maintenance and inspection that should be conducted on a regular basis are essential to longevity, and these elevators are the cornerstones of effective industrial functioning.

Industrial Goods Lift

An industrial goods lift is one lift that is constructed to transport the materials, stock, tools and goods up and down the building in a convenient manner. These lifts automate the operations at warehouses, factories, and assembly units. They are usually paved with large platforms, automatic gates and powerful lifting processes and high weight carrying capacities. Goods lifts enhance efficiency since it helps lower the risk of manual handling and accelerates the process.

Goods Lift Efficiency and Safety

There are the goods lifts, which has been used to streamline the industrial workflow by moving the material fast and safely through floors. High capacity motors, automatic gates, and reinforced platforms all make sure that there is safe handling of bulky or heavy loads. Goods lifts are necessary in modern factories and warehouses because correct lift installation, load monitoring, and planned maintenance decrease downtimes and minimize accidents in the workplace.

Freight Elevator

The biggest and most robust type of lift is a freight elevator which is applied in logistic centers, distribution hubs, shopping malls, airports, and storage warehouses. They are constructed to carry pallets, trolleys, heavy crates and machinery that is why they are reinforced with wide doors and impact resistant cabins. The freight elevators are of moderate speed yet are highly robust and stable.

Capacity and Durability

Freight elevators have been constructed to survive the harsh environment of heavy industrial transportation. Floors are reinforced, doors are oversized and lifting systems are very strong and offer maximum durability. Overload protection, impact resistant cabins and emergency controls are some of the safety mechanisms that make sure that the operation is safe. Such elevators are a necessity in logistics and manufacturing plants that need a high capacity and dependable transportation in the vertical direction.

Types of Mechanical & Hydraulic Lifts

Lifts employ differing mechanical systems based on the building requirements, height of the travel as well as the capability to carry.

Hydraulic Lift

A hydraulic lift is driven by fluid pressure with the help of a hydraulic cylinder. It suits low-rise constructions and areas where the machine room is not necessarily available. If you want to understand how these systems perform in different industrial settings, you can refer to this hydraulic lift guide. These lifts are characterized by smooth operation, good load capacity and low cost of installation. They however are usually slower in speed and need frequent fluid maintenance. Hydraulic systems are very popular in residential and small commercial applications.

Types of lifts that should be considered

To provide richness and fill in the entire range of lift technologies, introduced below are other lift systems that are popular in the current building design:

Machine-Room-Less (MRL) Lifts

Machine-room-less (MRL) lifts are small traction elevators that do not need an independent machine room, occupy less space, and need less construction work. They are energy efficient and best suited in buildings with low overhead space. These types of lifts are also smoother and have a lower level of noise that make them applicable in the contemporary residential and commercial applications.

Vacuum Elevators

Pneumatic or vacuum elevators are powered by air pressure and have minimal construction requirements thus are very common in luxury houses. They do not require a hole or a shaft so that they can be installed in available spaces rapidly. The fact that they are lightweight and transparent adds to interiors as well as offers the panoramic travel experience.

Traction Elevators

Traction elevators have ropes, pulleys and counterweights and therefore they can be adopted in mid-rise and high-rise buildings. They are quicker, move more easily and carry heavier than hydraulic lifts. These systems are used in commercial areas because they are efficient and reliable in the long run.

Customized Architectural Lifts

Architectural lifts are custom-made elevator systems that are constructed to look good such as circular, panoramic and completely glass industrial-elevators. They enhance the appearance of interiors and go hand-in-hand with high-quality building designs. Such lifts are usually applicable in hotels, show rooms and posh houses where appearance is important.

Key Factors to Consider When Choosing a Lift

To choose the appropriate lift, it is necessary to consider a number of crucial criteria:

Use purpose Passenger, goods, or mixed use. Residential lifts are oriented to comfort, whereas industrial lift is oriented to the heavy load.

- Capacity: Residential lightweight to heavy industrial.

- Space requirement: Pit depth, overhead clearance and machine room requirement. Small-sized products such as MRL lifts conserve space.

- Travel height: Floods and speed specifications. Aircraft buildings tend to require quicker traction lifts.

- Power mechanism: Hydraulic, traction or pneumatic based on building and load.

- Safety standards: Alarms, sensors, emergency brakes, and regulations.

- Maintenance requirements: Massage, availability of spares, and service.

- Cost factors: Cost of installation, operation and energy cost.

These factors are taken into consideration to make sure that the lift is safe, efficient and provides solutions to the long-term requirements.

Modern Innovations in Lift Technology

Over the past few years, remarkable changes have occurred in the lift industry, which are prompted by the use of smart technology, energy efficiency, and increased safety demands. Contemporary elevators are not only a vertical transportation device anymore, as they include highly developed control functions, Internet of Things, and predictive maintenance systems that enhance safety and decrease downtimes.

Such innovations are aimed to improve the passenger experience, increase the use of energy and raise the safety and usability of lifts. In the residential, commercial and industrial usage, the new lift technologies are concerned with performance, convenience and sustainability and present new building occupants and owners with modern and efficient solutions.

Key innovations include:

- Smart elevators: AI-powered dispatch, and level touchless control interfaces and optimal travel route.

- IoT lift systems: Remote monitoring, real-time fault reporting and predictive diagnostics.

- Energy efficient lifts: Regenerative lifts, low-power motors, and sustainability.

- Cutting noise and vibrations: Innovative guide shoes and ride comfort.

- Better safety precautions: Multi-sensor detection, automatic rescue system, and emergency measures.

Residential, Commercial vs Industrial Lifts

- Residential lifts: miniature, low-energy, attractive design.

- Commercial lifts: faster, more frequent, more developed safety.

- Industrial lifts: strong, massive, durable.

Conclusion

The knowledge of the different types of lifts assists a homeowner, architects, facility managers and industrial planners in selecting the appropriate system to meet their needs. It may be residential accessibility lift, commercial passenger, or industrial goods lift each has its purpose and benefits. A visit to the related pages will give more information on specifications, installation points, cost and technicalities. Knowing this, you are also able to make sound decisions which make any building project safe, efficient and long lasting and add convenience and overall user experience.

Frequently Asked Questions

What are the various variations of lifts used in a residential, commercial and industrial structure?

Lifts include home elevator lifts, platform lift, stair elevator chair, commercial elevator lift, dumbwaiter lift, commercial cargo lift, circular glass lift, industrial elevator lift, industrial goods lift, hydraulic lift and freight elevator. All of them are created to address unique requirements, e.g. residential comfort, commercial efficiency, or industrial heavy-duty application. These kinds of understanding assist in choosing the appropriate lift to space, load, and safety.

What is the benefit of a home elevator lift to enhance home mobility and convenience?

A home elevator lift is a small passenger lift that is used in homes. It hosts 2-4 people, is quiet and has low power consumption. It helps to make life more comfortable, increase the value of the property, and improve everyday mobility, which is ideal when it is used by elderly or disabled people. These lifts are versatile and can be used in hydraulic, traction, pneumatic, and machine-room-less designs and are safe and can fit well into the contemporary homes.

What is a platform lift and in which places can it be applied?

A platform lift is an access lift such as that designed to serve wheelchair users and people with mobility issues. It has an open platform and safety gates and not a complete cabin. It is commonly used in residences, educational institutions, healthcare facilities, and small offices, it needs not much space, and capable of short vertical coverage, including porches, mezzanines, or split-level houses.

What is the price of the lift in a house?

Installation of a lift in a house is dependent on the type, travel height, pit or shaft construction, safety, and cabin design variations. Hydraulic lifts tend to be pricier, platform lifts are less costly with vacuum lifts existing in the middle range. Other long-term costs such as the energy usage, maintenance, and warranty should also be in consideration during the planning of the total investment.

Commercial and industrial lifts-What is the difference between commercial and industrial lifts?

Commercial elevator lifts are used to transport passengers in shopping centers, hotels and offices and emphasize on speed, capacity and appearance. Dumbwaiter lifts are used in picking up small goods, whereas commercial cargo lifts are used in picking up heavy materials. Round glass elevators provide style and influence. Industrial goods lifts and industrial elevator lifts are constructed to support heavy loads, daily work and high safety requirements. Large machinery and pallets are transported by freight elevators. Both types are tailored to certain functional requirements, safety and efficiency.